-

Products

-

Solution

Solution

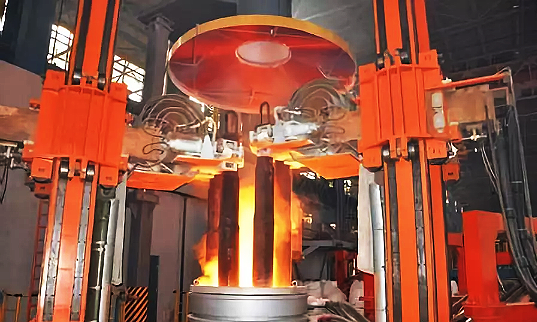

Provide customers with solutions in terms of improving power quality, optimizing control, and energy saving and consumption reduction.

Read more >

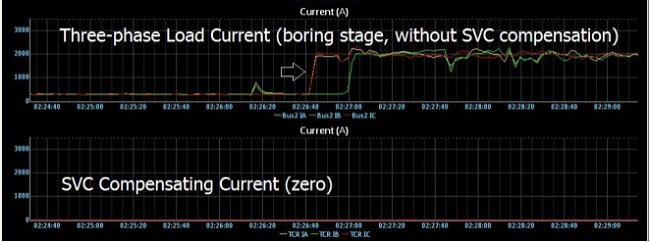

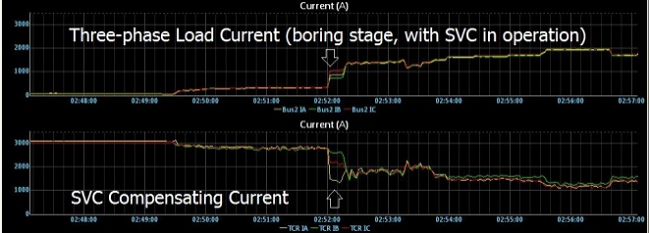

Improving power quality and optimizing control

-

Service

Service

Liaoning Rongxin Xingye Power Technology Co., Ltd. is committed to becoming a reliable partner of customers through honest management. In order to continuously improve the service quality.

Read more >

-

About us

About us

Rongxin Xingye is taking "Rongxin" as the foundation and "Xingye" as its mission, using the wisdom and diligence from China to provide global customers with high-quality products and services to achieve green life and sustainable development.

Read more >

-

Responsibility

Responsibility

"Rongrong grass and trees, longevity of faith", Rongxin Xingye advocates a green lifestyle

Read more >

-

News

News

Focus on energy efficiency and achieve sustainable social development with high-quality products, services and solutions.

Read more >

-

Join us

Join us

Focusing on the development goals of the company's strategic planning, absorbing the essence of corporate culture, and creating a sound, efficient and innovative human resource system.

Read more >

-

Contact us

Contact us

Liaoning Rongxin Xingye Power Technology Co., Ltd. was established in March 2017. It is a high-tech enterprise focusing on the manufacture of energy-saving and high-power power electronic equipment.

Read more >