Application of RSVG in EAF -- CangzhouLingang MITSUBISHI

Electric arc furnace (EAF) is a kind of electric furnace which uses the heat generated by electric arc to smelt metal. With the comprehensive ban of intermediate frequency furnace by the state, more and more EAFs have been applied in recent years, and most of them are ultra-high power. The load characteristics of electric arc furnace are nonlinear and time-varying, and its power quality is very poor, which will cause many system power quality problems, such as voltage flicker and fluctuation, large negative sequence component, more harmonics, low power factor and so on. Among many power quality problems caused by electric arc furnace, voltage flicker is the most difficult to control. Because voltage flicker is caused by the irregular fluctuation of reactive power and voltage, requirement for response speed and compensation accuracy of the compensation device are very high. Because SVC is based on semi controlled thyristor, the response time of SVC is usually more than 10 ms, and the best flicker suppression ratio that it can achieve is 2:1. The SVG based on VSC scheme has the advantage of fast response, which can theoretically achieve a flicker suppression ratio of more than 5:1. Although H-bridge cascaded SVG has been widely used in 10kV and 35kV medium voltage power systems, few SVGs have been successfully used in EAF load compensation in China.

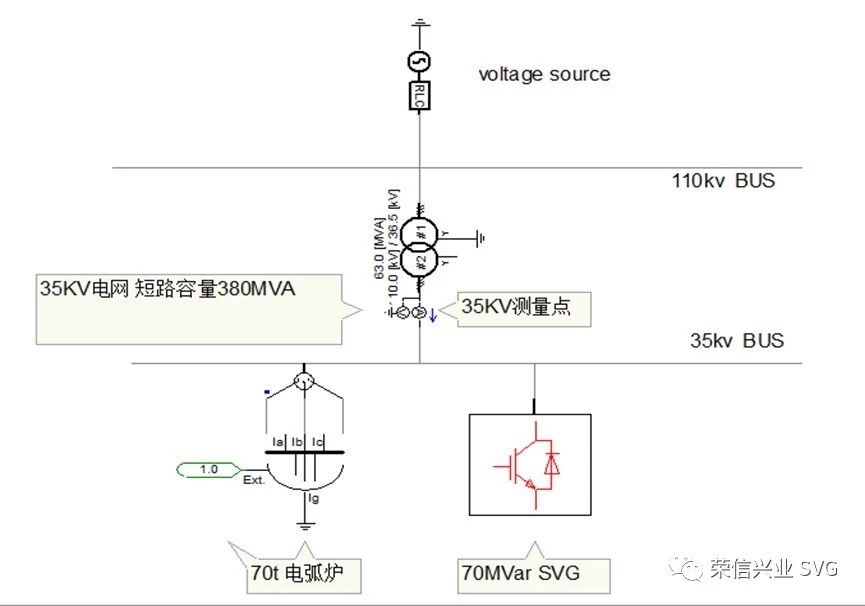

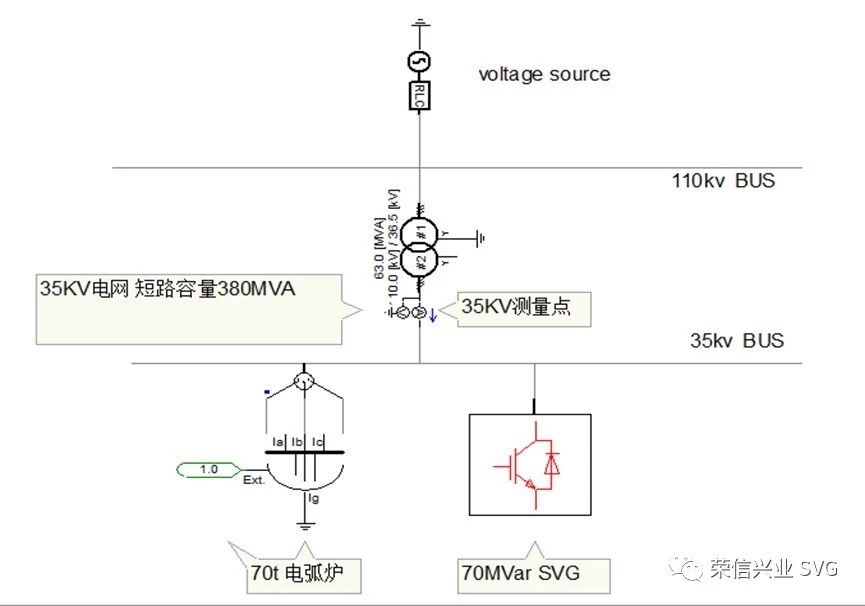

In August 2017, Liaoning RongxinXingye Power Technology Co., Ltd. signed the contract of 35kV dynamic reactive power generator SVG for Cangzhou Lingang Mitsubishi metal EAF, with voltage level of 35kV and capacity of 70MVar. The main wiring diagram is as follows:

After using the SVG to compensate the 50 MVA AC arc, the power quality problem is improved obviously. Among them, the average power factor is higher than 0.99, the overall compensation rate of harmonic current is more than 68%, the compensation rate of main harmonic components is more than 80%, and the flicker suppression ratio is about 5.

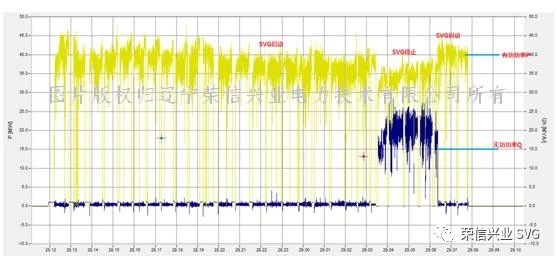

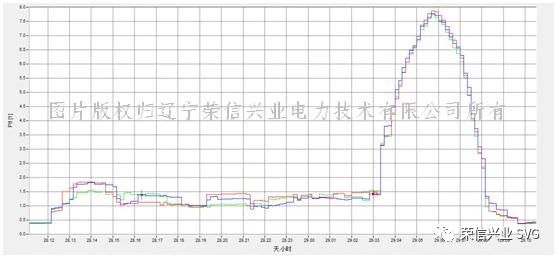

The figure above shows the curve of three-phase reactive power and active power before and after SVG startup.

It can be seen from the figure that the maximum reactive power impact of the system before compensation is close to 30MVar, and the maximum reactive power impact of the system after compensation is lower than 4MVar. It can be seen from the active power curve that after compensation, the active power of the system has been significantly improved due to the stable grid voltage, which is conducive to improving the smelting speed.

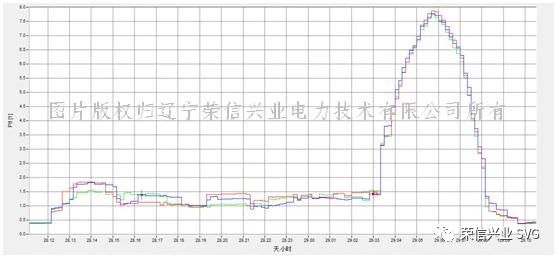

The figure above shows the curve of three-phase average power factor before and after SVG startup.

It can be seen from the figure that the average power factor before the start of SVG is0.9, which is lower than the bottom limit of national standard, and the average power factor after the start of SVG is higher than 0.99.

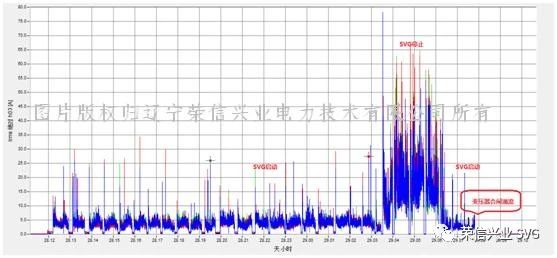

By spectrum analysis, the main harmonic component of EAF current is the third order harmonic. Figure 5 shows the third harmonic current curve before and after SVG startup. The harmonic current before compensation is more than 30A, and the harmonic current after compensation is about 5A. After calculation, third and fifth of the grid current before compensation exceed the national standard. After compensation, all harmonics meet the national standard. The overall harmonic compensation rate is 68.25%, and the third harmonic current suppression rate is 82.69%. The total distortion rate of harmonic voltage before compensation is 3.23%, which exceeds the national standard limit of 3%, and the total distortion rate of harmonic voltage after compensation is 1.29%.

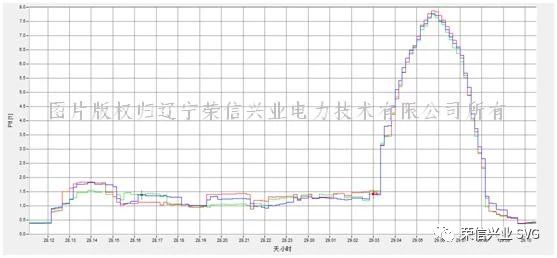

The short-term flicker Pst curve before and after compensation is shown in the above figure.

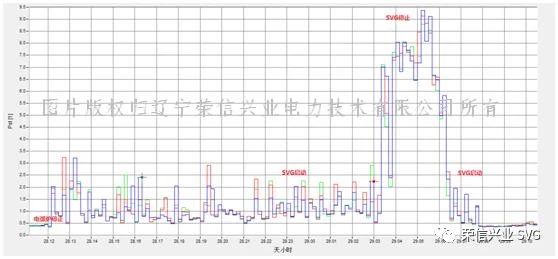

The long-term flicker Plt curve before and after compensation is shown in the above figure.

Plt in the figure is calculated by 2-hours moving average. The flicker suppression ratio is about 5. To sum up, SVG realizes the comprehensive compensation for reactive power, harmonic and flicker of EAF load.

After using the SVG to compensate the 50 MVA AC arc, the power quality problem is improved obviously. Among them, the average power factor is higher than 0.99, the overall compensation rate of harmonic current is more than 68%, the compensation rate of main harmonic components is more than 80%, and the flicker suppression ratio is about 5.

After using the SVG to compensate the 50 MVA AC arc, the power quality problem is improved obviously. Among them, the average power factor is higher than 0.99, the overall compensation rate of harmonic current is more than 68%, the compensation rate of main harmonic components is more than 80%, and the flicker suppression ratio is about 5.